NITOCUT cutting system

Ultra-fast cutting

NITOCUT is the first manual cutting system in the world for a peripheral speed of 100 m/s.

The cut-off wheel developed by PFERD is characterized by its top cutting performance and outstanding tool life.

The NITOCUT cutting system allows faster working and up to four times more cuts as well as a higher insertion depth than the cut-off wheels common on the market with the dimensions 125 x 1.0 mm. The unique cutting system meets the highest quality and safety standards.

Advantages:

- Ultimate cutting performance and tool life due to significantly increased cutting speed.

- High insertion depth.

- Unique, convenient cutting experience.

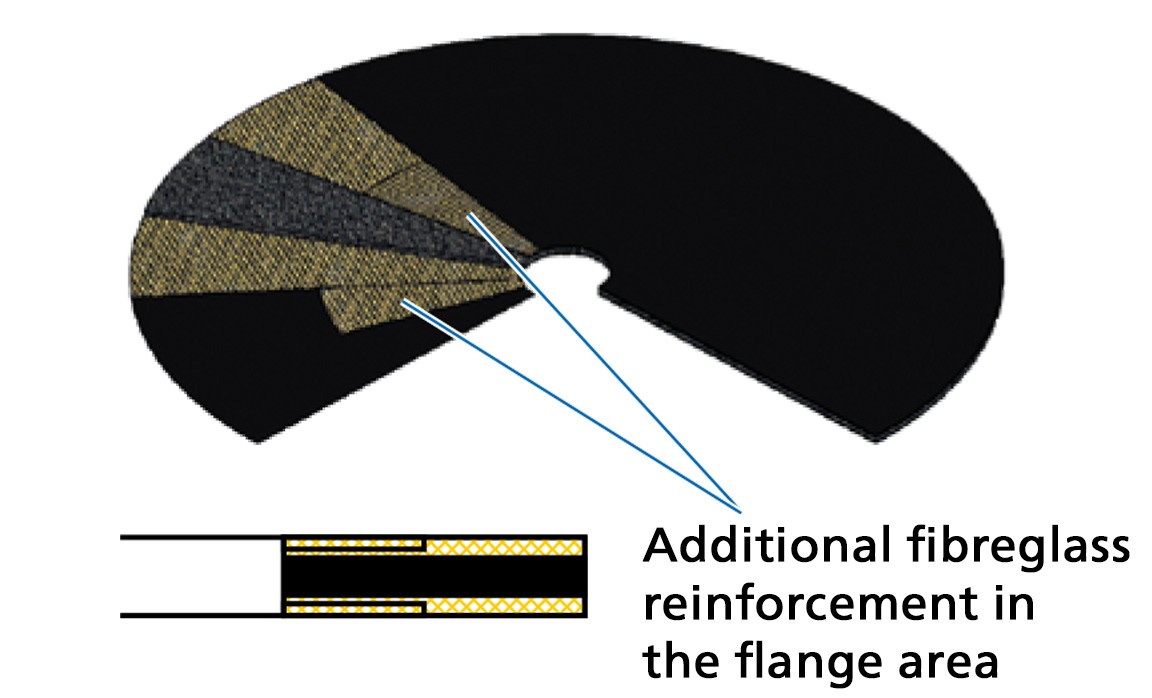

- Extremely high cut-off wheel reliability thanks to innovative fibreglass reinforcement.

Recommendations for use:

- The 100 m/s cutting system can be used like any conventional angle grinders.

Safety notes:

- Common cut-off wheels achieve a peripheral speed of a maximum of 80 m/s. They must not be used on the NITOCUT angle grinder.

- In order to prevent misuse, the specially produced angle grinder only allows the assembly of NITOCUT cut-off wheels.