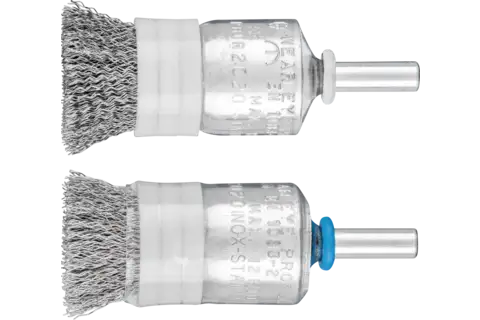

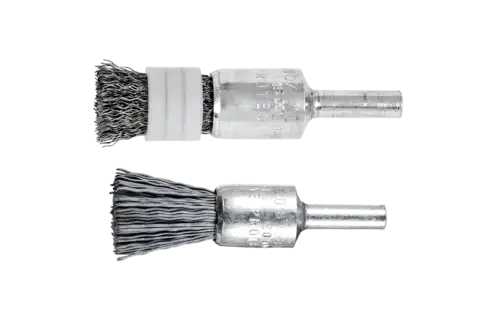

End brushes crimped with bridle, shank-mounted

6 of 9 Product variants

| Item number / EAN | Dia. external | Dia. filament material | Filament material | PU Packaging unit | Please login to see the price |

|---|---|---|---|---|---|

| 43212003 / 4007220531020 PBUR 1316/6 INOX 0,20 | 13 mm | 0.2 mm | Stainless steel wire (INOX) | 10 pieces | Login / Register |

| 43212001 / 4007220530962 PBUR 1316/6 ST 0,20 | 13 mm | 0.2 mm | Steel wire (ST) | 10 pieces | Login / Register |

| 43215001 / 4007220530979 PBUR 1316/6 ST 0,35 | 13 mm | 0.35 mm | Steel wire (ST) | 10 pieces | Login / Register |

| 43213004 / 4007220531037 PBUR 2022/6 INOX 0,20 | 20 mm | 0.2 mm | Stainless steel wire (INOX) | 10 pieces | Login / Register |

| 43213001 / 4007220530986 PBUR 2022/6 ST 0,20 | 20 mm | 0.2 mm | Steel wire (ST) | 10 pieces | Login / Register |

| 43213002 / 4007220530993 PBUR 2022/6 ST 0,35 | 20 mm | 0.35 mm | Steel wire (ST) | 10 pieces | Login / Register |

| 43214004 / 4007220531044 PBUR 2530/6 INOX 0,20 | 25 mm | 0.2 mm | Stainless steel wire (INOX) | 10 pieces | Login / Register |

| 43214001 / 4007220531006 PBUR 2530/6 ST 0,20 | 25 mm | 0.2 mm | Steel wire (ST) | 10 pieces | Login / Register |

| 43214002 / 4007220531013 PBUR 2530/6 ST 0,35 | 25 mm | 0.35 mm | Steel wire (ST) | 10 pieces | Login / Register |