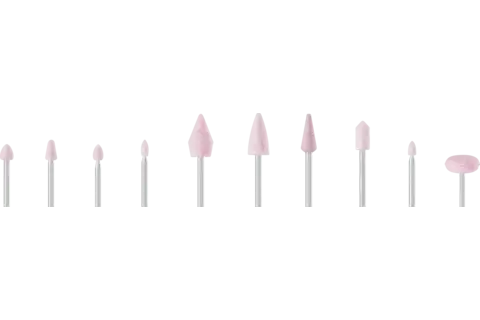

6 of 37 Product variants

| Item number / EAN | Dia. external | Dia. shank | Grit size | Shape | Width | PU Packaging unit | Please login to see the price |

|---|---|---|---|---|---|---|---|

| 35662278 / 4007220117842 B 102 3 AR 80 O5V STEEL EDGE | 16 mm | 3 mm | 80 | B 102 | 13 mm | 10 pieces | Login / Register |

| 35663278 / 4007220117866 B 103 3 AR 80 O5V STEEL EDGE | 16 mm | 3 mm | 80 | B 103 | 5 mm | 10 pieces | Login / Register |

| 35665270 / 4007220117880 B 105 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 105 | 6 mm | 10 pieces | Login / Register |

| 35674270 / 4007220117958 B 114 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 114 | 10 mm | 10 pieces | Login / Register |

| 35675270 / 4007220117965 B 115 3 AR 100 O5V STEEL EDGE | 2 mm | 3 mm | 100 | B 115 | 3 mm | 10 pieces | Login / Register |

| 35681274 / 4007220117972 B 121 3 AR 46 O5V STEEL EDGE | 13 mm | 3 mm | 46 | B 121 | 13 mm | 10 pieces | Login / Register |

| 35682274 / 4007220117996 B 122 3 AR 46 O5V STEEL EDGE | 10 mm | 3 mm | 46 | B 122 | 10 mm | 10 pieces | Login / Register |

| 35682278 / 4007220118009 B 122 3 AR 80 O5V STEEL EDGE | 10 mm | 3 mm | 80 | B 122 | 10 mm | 10 pieces | Login / Register |

| 35683270 / 4007220118016 B 123 3 AR 100 O5V STEEL EDGE | 5 mm | 3 mm | 100 | B 123 | 5 mm | 10 pieces | Login / Register |

| 35684270 / 4007220118023 B 124 3 AR 100 O5V STEEL EDGE | 3 mm | 3 mm | 100 | B 124 | 3 mm | 10 pieces | Login / Register |

| 35685270 / 4007220118030 B 125 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 125 | 6 mm | 10 pieces | Login / Register |

| 35185270 / 4007220115732 B 125 3,1 AR 100 O5V STEEL EDGE | 6 mm | 3.17 mm | 100 | B 125 | 6 mm | 10 pieces | Login / Register |

| 35603270 / 4007220117453 B 43 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 43 | 8 mm | 10 pieces | Login / Register |

| 35604270 / 4007220117460 B 44 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 44 | 10 mm | 10 pieces | Login / Register |

| 35605270 / 4007220117477 B 45 3 AR 100 O5V STEEL EDGE | 5 mm | 3 mm | 100 | B 45 | 8 mm | 10 pieces | Login / Register |

| 35606270 / 4007220117484 B 46 3 AR 100 O5V STEEL EDGE | 3 mm | 3 mm | 100 | B 46 | 8 mm | 10 pieces | Login / Register |

| 35611278 / 4007220117507 B 51 3 AR 80 O5V STEEL EDGE | 11 mm | 3 mm | 80 | B 51 | 19 mm | 10 pieces | Login / Register |

| 35612274 / 4007220117514 B 52 3 AR 46 O5V STEEL EDGE | 10 mm | 3 mm | 46 | B 52 | 19 mm | 10 pieces | Login / Register |

| 35612278 / 4007220117521 B 52 3 AR 80 O5V STEEL EDGE | 10 mm | 3 mm | 80 | B 52 | 19 mm | 10 pieces | Login / Register |

| 35613270 / 4007220117538 B 53 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 53 | 16 mm | 10 pieces | Login / Register |

| 35613276 / 4007220117545 B 53 3 AR 60 O5V STEEL EDGE | 6 mm | 3 mm | 60 | B 53 | 16 mm | 10 pieces | Login / Register |

| 35614270 / 4007220117552 B 54 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 54 | 13 mm | 10 pieces | Login / Register |

| 35614276 / 4007220117569 B 54 3 AR 60 O5V STEEL EDGE | 6 mm | 3 mm | 60 | B 54 | 13 mm | 10 pieces | Login / Register |

| 35615270 / 4007220117576 B 55 3 AR 100 O5V STEEL EDGE | 3 mm | 3 mm | 100 | B 55 | 6 mm | 10 pieces | Login / Register |

| 35621278 / 4007220117590 B 61 3 AR 80 O5V STEEL EDGE | 19 mm | 3 mm | 80 | B 61 | 8 mm | 10 pieces | Login / Register |

| 35624270 / 4007220117637 B 64 3 AR 100 O5V STEEL EDGE | 6 mm | 3 mm | 100 | B 64 | 2 mm | 10 pieces | Login / Register |

| 35629270 / 4007220117668 B 69 3 AR 100 O5V STEEL EDGE | 8 mm | 3 mm | 100 | B 69 | 2 mm | 10 pieces | Login / Register |

| 35630270 / 4007220117675 B 70 3 AR 100 O5V STEEL EDGE | 19 mm | 3 mm | 100 | B 70 | 3 mm | 10 pieces | Login / Register |

| 35631270 / 4007220117682 B 71 3 AR 100 O5V STEEL EDGE | 16 mm | 3 mm | 100 | B 71 | 2 mm | 10 pieces | Login / Register |

| 35632270 / 4007220117699 B 72 3 AR 100 O5V STEEL EDGE | 13 mm | 3 mm | 100 | B 72 | 3 mm | 10 pieces | Login / Register |

| 35633270 / 4007220117705 B 73 3 AR 100 O5V STEEL EDGE | 13 mm | 3 mm | 100 | B 73 | 3 mm | 10 pieces | Login / Register |

| 35641270 / 4007220117712 B 81 3 AR 100 O5V STEEL EDGE | 19 mm | 3 mm | 100 | B 81 | 8 mm | 10 pieces | Login / Register |

| 35642270 / 4007220117736 B 82 3 AR 100 O5V STEEL EDGE | 13 mm | 3 mm | 100 | B 82 | 6 mm | 10 pieces | Login / Register |

| 35655270 / 4007220117798 B 95 3 AR 100 O5V STEEL EDGE | 3 mm | 3 mm | 100 | B 95 | 5 mm | 10 pieces | Login / Register |

| 35656270 / 4007220117804 B 96 3 AR 100 O5V STEEL EDGE | 3 mm | 3 mm | 100 | B 96 | 6 mm | 10 pieces | Login / Register |

| 35657270 / 4007220117811 B 97 3 AR 100 O5V STEEL EDGE | 2 mm | 3 mm | 100 | B 97 | 10 mm | 10 pieces | Login / Register |

| 35658270 / 4007220117828 B 98 3 AR 100 O5V STEEL EDGE | 2 mm | 3 mm | 100 | B 98 | 6 mm | 10 pieces | Login / Register |