Training courses and workshops

Learn from the best!

Benefit from over 200 years of experience in machining materials – PFERD is a pioneer when it comes to the development, production, consulting, as well as sales of tool solutions for working on surfaces and cutting materials.

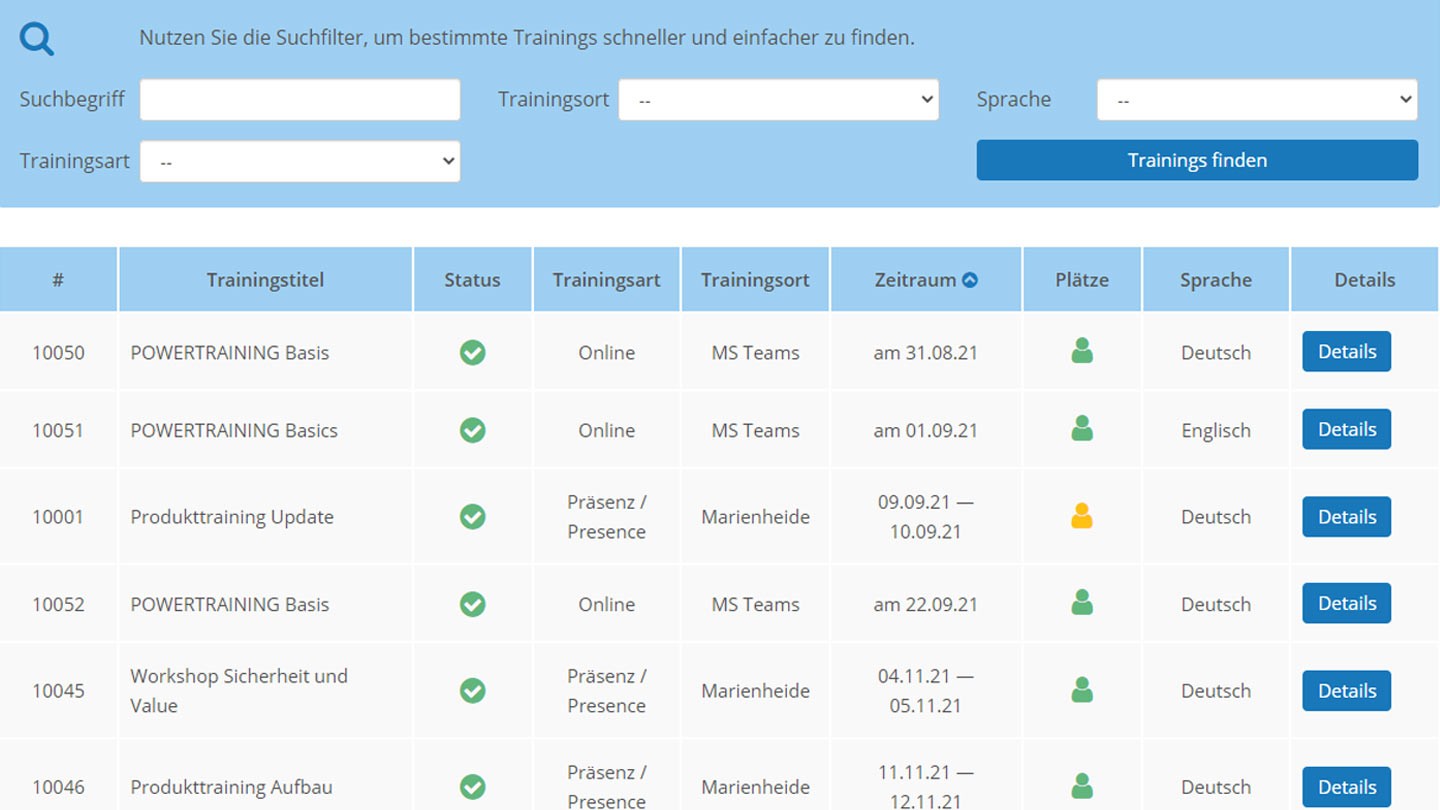

In-depth knowledge of the interactions of tool, material and tool drive forms the foundation for the optimization of machining processes. In the PFERDACADEMY, we provide highly specialized and practical knowledge from the world of grinding and cutting. The seminar blocks follow on from each other, so step by step you will become a PFERD tool specialist.

The different training courses can be held in the modern facilities at the PFERDACADEMY, at the PFERD subsidiaries or directly at the customer’s premises.

For an individual registration please contact your sales representative.