|

40572 / 42799011

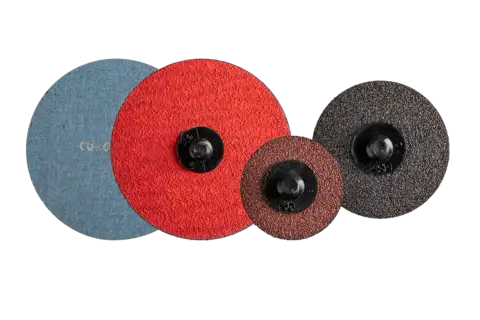

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDFR, 120 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

1 1/2 Inch

|

120

|

100 pieces

|

Login / Register

|

|

40570 / 42799010

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDFR, 50 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

1 1/2 Inch

|

50

|

100 pieces

|

Login / Register

|

|

40571 / 47201013

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDFR, 80 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

1 1/2 Inch

|

80

|

100 pieces

|

Login / Register

|

|

40575 / 42799013

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDFR, 120 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

2 Inch

|

120

|

100 pieces

|

Login / Register

|

|

40573 / 42799012

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDFR, 50 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

2 Inch

|

50

|

100 pieces

|

Login / Register

|

|

40574 / 47201007

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDFR, 80 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

2 Inch

|

80

|

100 pieces

|

Login / Register

|

|

40578 / 42799015

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDFR, 120 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

3 Inch

|

120

|

50 pieces

|

Login / Register

|

|

40576 / 42799014

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDFR, 50 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

3 Inch

|

50

|

50 pieces

|

Login / Register

|

|

40577 / 47201014

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDFR, 80 Grit, Ceramic CO-COOL

|

RS ceramic oxide grain CO-COOL version

|

CDR system

|

3 Inch

|

80

|

50 pieces

|

Login / Register

|

|

40602 / 42799027

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR,120 Grit,Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

1 1/2 Inch

|

120 PLUS

|

100 pieces

|

Login / Register

|

|

40600 / 42799025

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR, 60 Grit,Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

1 1/2 Inch

|

60 PLUS

|

100 pieces

|

Login / Register

|

|

40601 / 42799026

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR, 80 Grit,Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

1 1/2 Inch

|

80 PLUS

|

100 pieces

|

Login / Register

|

|

40587 / 42799018

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR, 120 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

1 1/2 Inch

|

120

|

100 pieces

|

Login / Register

|

|

40585 / 42799016

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR, 60 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

1 1/2 Inch

|

60

|

100 pieces

|

Login / Register

|

|

40586 / 42799017

COMBIDISC® RS Abrasive Disc, 1-1/2" Dia, Type CDR, 80 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

1 1/2 Inch

|

80

|

100 pieces

|

Login / Register

|

|

40605 / 42799030

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 120 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

2 Inch

|

120 PLUS

|

100 pieces

|

Login / Register

|

|

40603 / 42799028

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 60 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

2 Inch

|

60 PLUS

|

100 pieces

|

Login / Register

|

|

40604 / 42799029

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 80 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

2 Inch

|

80 PLUS

|

100 pieces

|

Login / Register

|

|

40590 / 42799021

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 120 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

2 Inch

|

120

|

100 pieces

|

Login / Register

|

|

40588 / 42799019

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 60 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

2 Inch

|

60

|

100 pieces

|

Login / Register

|

|

40589 / 42799020

COMBIDISC® RS Abrasive Disc, 2" Dia, Type CDR, 80 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

2 Inch

|

80

|

100 pieces

|

Login / Register

|

|

40608" / 42799033

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 120 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

3 Inch

|

120 PLUS

|

50 pieces

|

Login / Register

|

|

40606 / 42799031

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 60 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

3 Inch

|

60 PLUS

|

50 pieces

|

Login / Register

|

|

40607 / 42799032

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 80 Grit, Aluminum oxide A-PLUS

|

RS aluminium oxide A-PLUS version

|

CDR system

|

3 Inch

|

80 PLUS

|

50 pieces

|

Login / Register

|

|

40593 / 42799024

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 120 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

3 Inch

|

120

|

50 pieces

|

Login / Register

|

|

40591 / 42799022

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 60 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

3 Inch

|

60

|

50 pieces

|

Login / Register

|

|

40592 / 42799023

COMBIDISC® RS Abrasive Disc, 3" Dia, Type CDR, 80 Grit, Silicon Carbide

|

RS silicon carbide SiC version

|

CDR system

|

3 Inch

|

80

|

50 pieces

|

Login / Register

|