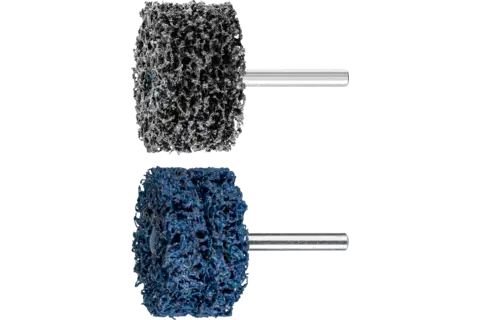

5 of 5 Product variants

| EDP / Item number Global part number | Dia. external | Version | Width | PU Box quantity | Please login to see the price |

|---|---|---|---|---|---|

| 44888 / 47803120 POLICLEAN® PLUS Mounted Wheel, 4" x 1/2, 1/4" Shank, Aluminum oxide | 4 Inch | PCLZY PLUS | 1/2 Inch | 5 pieces | Login / Register |

| 44884 / 47803116 POLICLEAN® PLUS Mounted Wheel, 2" x 1/2, 1/4" Shank, Aluminum oxide | 2 Inch | PCLZY PLUS | 1/2 Inch | 5 pieces | Login / Register |

| 44885 / 47803117 POLICLEAN® PLUS Mounted Wheel, 2" x 1, 1/4" Shank, Aluminum oxide | 2 Inch | PCLZY PLUS | 1 Inch | 5 pieces | Login / Register |

| 44886 / 47803118 POLICLEAN® PLUS Mounted Wheel, 3" x 1/2, 1/4" Shank, Aluminum oxide | 3 Inch | PCLZY PLUS | 1/2 Inch | 5 pieces | Login / Register |

| 44887 / 47803119 POLICLEAN® PLUS Mounted Wheel, 3" x 1, 1/4" Shank, Aluminum oxide | 3 Inch | PCLZY PLUS | 1 Inch | 5 pieces | Login / Register |