|

39083 / 33400034

Discontinued

|

220

|

1/8 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39089 / 33400040

Discontinued

|

320

|

1/8 Inch

|

1/2 Inch

|

12 pieces

|

Login / Register

|

|

39095 / 33400046

Discontinued

|

400

|

1/8 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39101 / 33400052

Discontinued

|

600

|

1/8 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39078 / 33400029

Discontinued

|

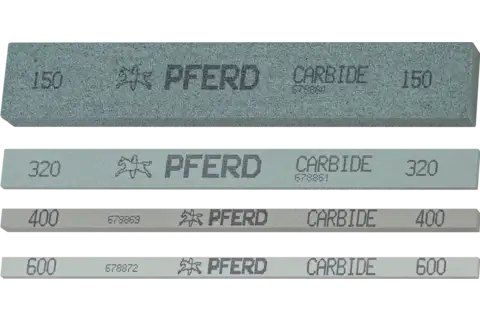

150

|

1/4 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39084 / 33400035

Discontinued

|

220

|

1/4 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39090 / 33400041

Discontinued

|

320

|

1/4 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39096 / 33400047

Discontinued

|

400

|

1/4 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39102 / 33400053

Discontinued

|

600

|

1/4 Inch

|

1/2 Inch

|

1 piece

|

Login / Register

|

|

39079 / 33400030

Discontinued

|

150

|

1/2 Inch

|

1 Inch

|

1 piece

|

Login / Register

|

|

39085 / 33400036

Discontinued

|

220

|

1/2 Inch

|

1 Inch

|

1 piece

|

Login / Register

|

|

39091 / 33400042

Discontinued

|

320

|

1/2 Inch

|

1 Inch

|

1 piece

|

Login / Register

|

|

39097 / 33400048

Discontinued

|

400

|

1/2 Inch

|

1 Inch

|

1 piece

|

Login / Register

|

|

39103 / 33400054

Discontinued

|

600

|

1/2 Inch

|

1 Inch

|

1 piece

|

Login / Register

|

|

39074 / 33400025

Discontinued

|

150

|

5/32 Inch

|

5/32 Inch

|

1 piece

|

Login / Register

|

|

39080 / 33400031

Discontinued

|

220

|

5/32 Inch

|

5/32 Inch

|

1 piece

|

Login / Register

|

|

39086 / 33400037

Discontinued

|

320

|

5/32 Inch

|

5/32 Inch

|

1 piece

|

Login / Register

|

|

39075 / 33400026

Discontinued

|

150

|

1/8 Inch

|

1/4 Inch

|

1 piece

|

Login / Register

|

|

39081 / 33400032

Discontinued

|

220

|

1/8 Inch

|

1/4 Inch

|

1 piece

|

Login / Register

|

|

39099 / 33400050

Discontinued

|

600

|

1/8 Inch

|

1/4 Inch

|

1 piece

|

Login / Register

|

|

39076 / 33400027

Discontinued

|

150

|

1/4 Inch

|

1/4 Inch

|

12 pieces

|

Login / Register

|

|

39082 / 33400033

Discontinued

|

220

|

1/4 Inch

|

1/4 Inch

|

1 piece

|

Login / Register

|

|

39088 / 33400039

Discontinued

|

320

|

1/4 Inch

|

1/4 Inch

|

1 piece

|

Login / Register

|