Countersink tools

The universal product range for industry and professional trade

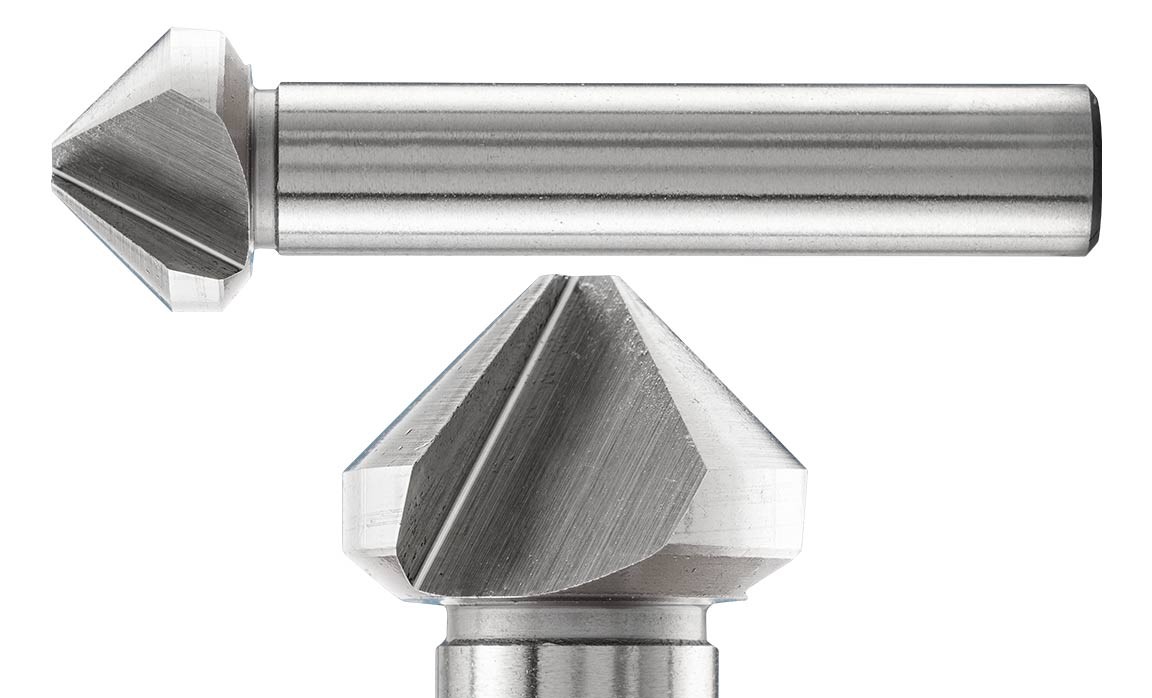

Countersink tools - HSS conical countersinks

Conical countersinks from PFERD are characterized by their particularly sharp blades that are able to achieve very good results, even at low cutting speeds. The various versions allow for countersinking and deburring when machining various types of materials, even in industrial environments. The UGT version denotes a conical countersink with unequal pitch. To ensure reliable torque transmission, conical countersinks have a three-surface shaft from a countersink diameter of 28 mm.

PFERD also offers conical countersinks with a premium HICOAT coating. Tapered countersinks with a HICOAT coating provide good high-temperature hardness and resistance to oxidation. They can therefore also be used on hard materials without the addition of coolants.

Advantages:

- Very high stock removal rate and optimum chip removal.

- Burr-free results, even with low cutting speeds.

- Long tool life.

- High surface quality of the workpiece.

HSS type

- HSS countersink that is suitable for universal use on almost all materials.

HSS E Co5 (M35) type

- HSS countersink that is suitable for universal use on almost all materials.

- Long tool life.

- Very good temperature resistance due to Co content.

HSS HICOAT HC-FEP type

- HSS countersink that is suitable for universal use on almost all materials.

- Very long tool life thanks to premium HICOAT coating.

- Can also be used without coolants and lubricants.

HSS countersinks 90°

- Particularly well suited for producing countersinks for 90° screws.

HSS countersinks 90° with unequal pitch (UGT)

- Particularly well suited to producing exact countersinks.

- Smooth running.

- Low countersinking force and a good surface quality.

- Specially developed geometry with wide flutes for optimal chip removal and heat dissipation.

- Especially well suited for robot and stationary applications.

HSS countersinks 60°

- Particularly well suited for countersinking and deburring.

Countersink tools - HSS flat countersinks

High-performance flat countersinks made from HSS according to DIN 373 for countersinking cylinder head and hexagon screws as well as nuts. Flat countersinks have a cylindrical design. The cylindrical pin in the relevant quality grades of fine, medium or tapping hole ensures coaxial alignment of the countersink to the bore.

Advantages:

- Very high stock removal rate.

- Optimum chip removal.

- Burr-free results.

- Long tool life.

- Smooth operation.

- Good surface quality.

Quality grade fine (F)

- Flat countersinks with the quality grade of fine are suitable for producing flat countersinks at through holes or blind holes in the tolerance range of fine with high mounting accuracy.

Quality grade medium (M)

- Flat countersinks with the quality grade medium are suitable for producing flat countersinks at through holes or blind holes in the tolerance range of medium with extended mounting accuracy.

For tapping hole (GKL)

- Flat countersinks for the tapping hole are suitable for producing flat countersinks at core holes for female threads.