TC burrs - EDGE cut

Tungsten carbide burrs for work on edges represent a separate PFERD product line. They are mainly used in steel and aluminium construction.

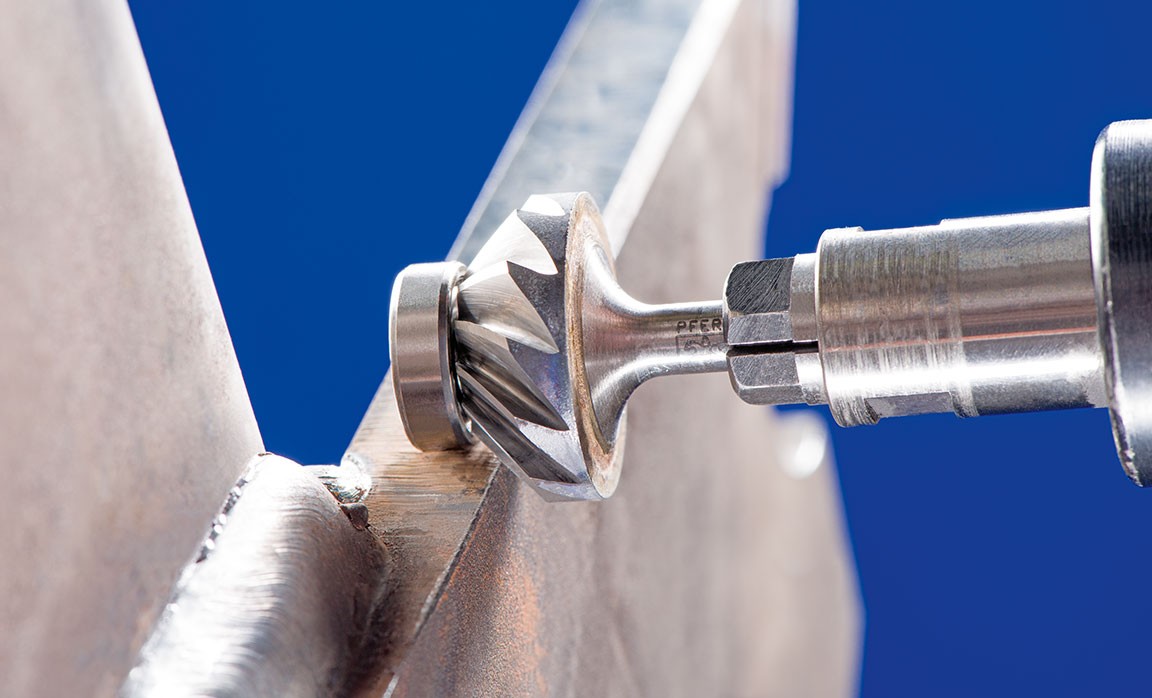

Tungsten carbide burrs with the EDGE cut have been especially developed for defined work on edges. The special design allows the burr to run directly along the edges without damaging the workpiece.

Exact edge shapes can therefore be created in a single step – with either defined chamfers of 30° or 45°, or to a defined radius of 3.0 mm. Among other things, rounding edges is a precautionary measure for anti-corrosion protection according to ISO 12944-3, ISO 8501-3, SOLAS XII/6.3 (Ref. T4/3.01 MSC.1/Circ.1198).

Advantages:

- Special design for precise guidance.

- Safe and comfortable to guide.

- Create exact edge shapes in a single step.

Materials that can be worked:

- Steel and cast steel

- Stainless steel (INOX)

- Non-ferrous metals

- Cast iron

- Plastics, other materials

Applications:

- Defined work on edges

- Defined deburring

- Breaking and rounding edges in steel and aluminium construction

- Rounding edges in preparation for the application of anti-corrosion coatings in shipbuilding, on crane systems and other steel constructions which are exposed to corrosion loading

- Defined chamfering for weld seam preparation for V-shaped seams (60°, ISO 9692-1)

- Defined chamfering for edge breaking (45°)

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot

- Machine tools

Recommendations for use:

- Use the burrs counter rotationally.

- In order to produce a fine surface, finally pass them over the edges in the direction of rotation.

- If possible, use EDGE cut burrs with the PFERD compressed-air straight grinder PG 3/210 with matching guide sleeve EFH PG 3/210 (see the info box on the right).

EDGE Cutting System (ECS)

The EDGE Cutting System consists of burrs with the EDGE cut and a special guide sleeve. The system can be positioned on any conventional drive to ensure optimal guidance during light deburring work.

Advantages:

- Improved guidance.

- Can be used with any conventional straight grinder.

- Burr is interchangeable.